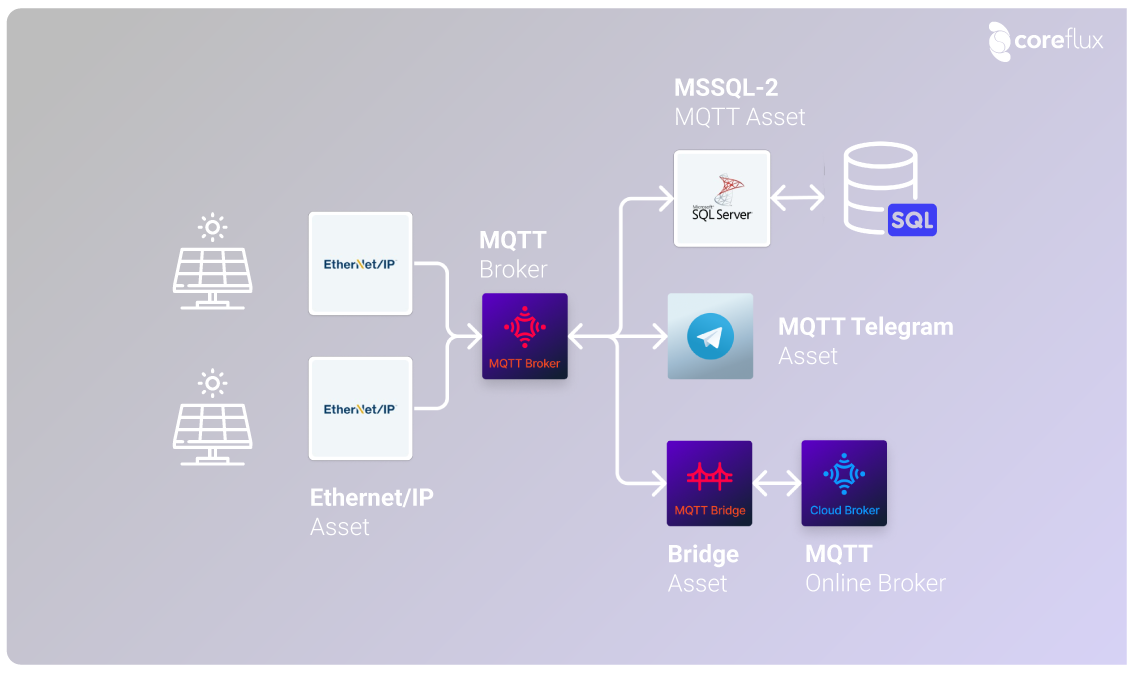

Energy / Renewables

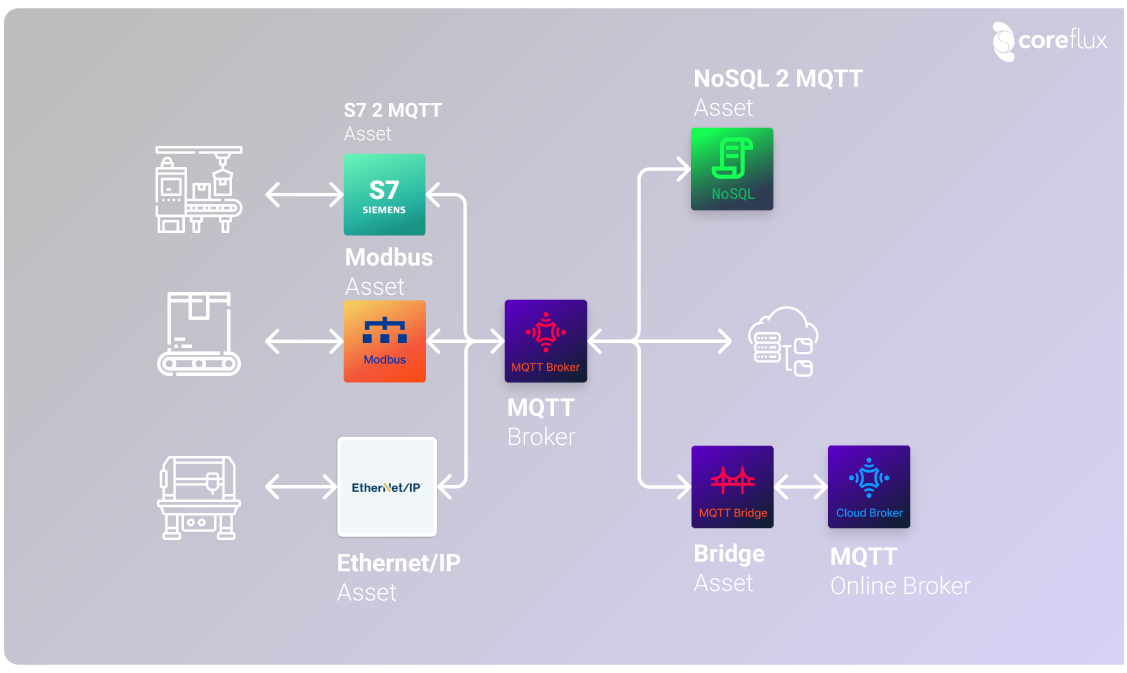

Industry 4.0

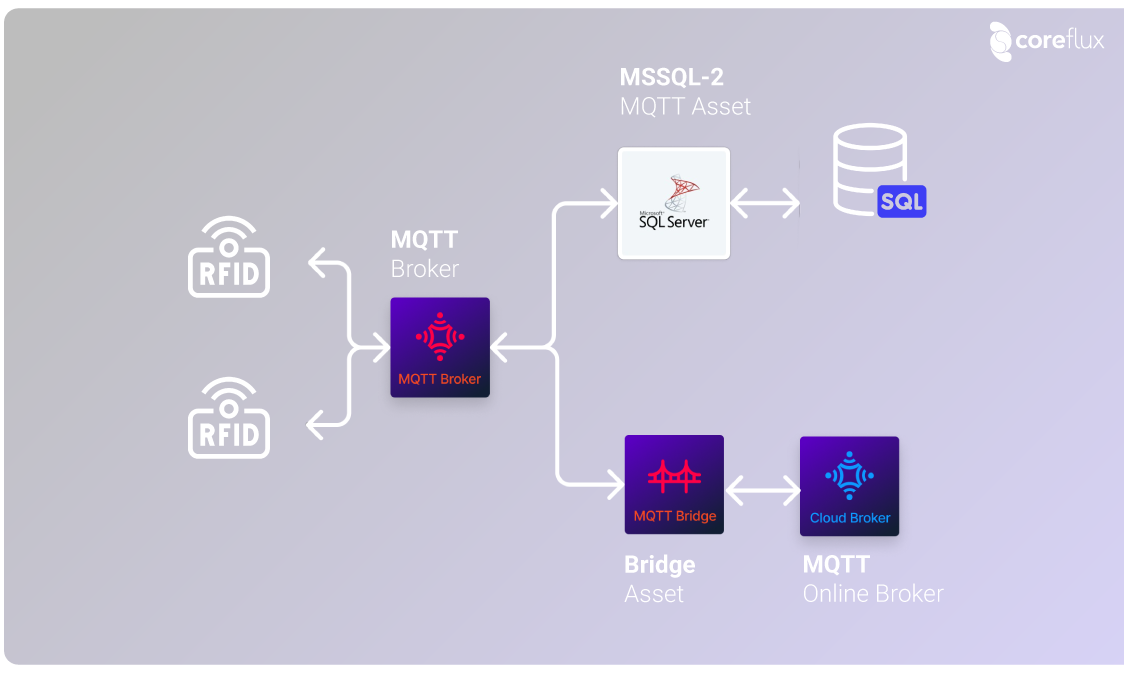

Logistics

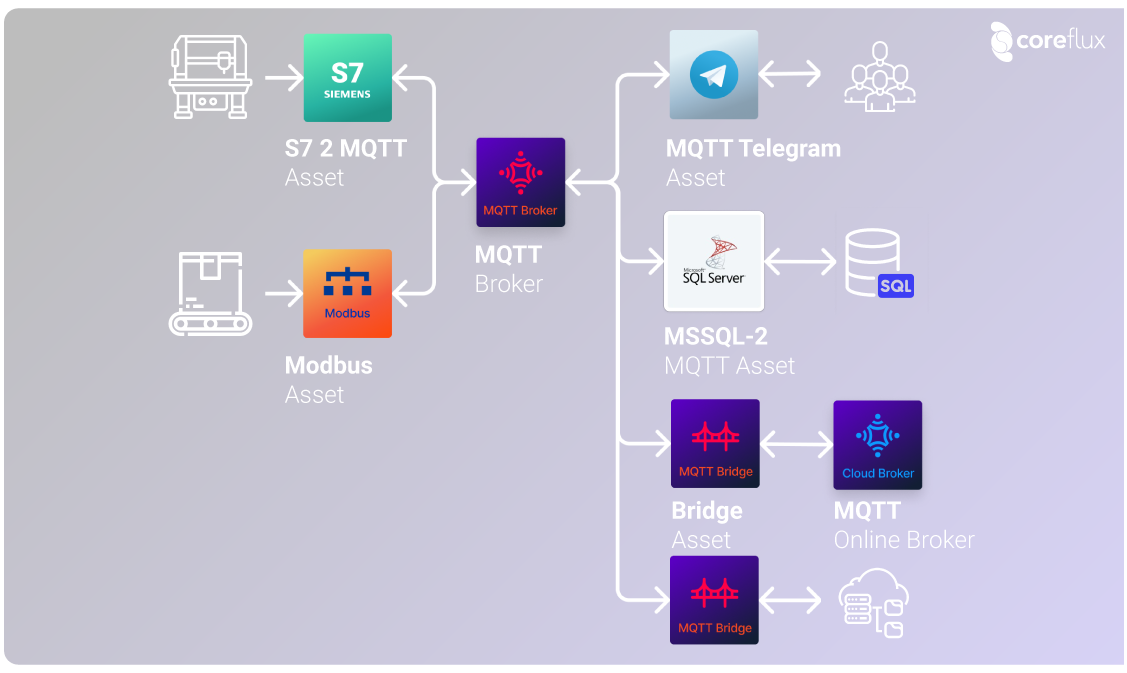

Industry 4.0

Machine Building

Industry 4.0

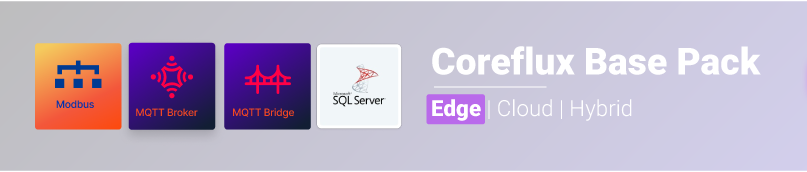

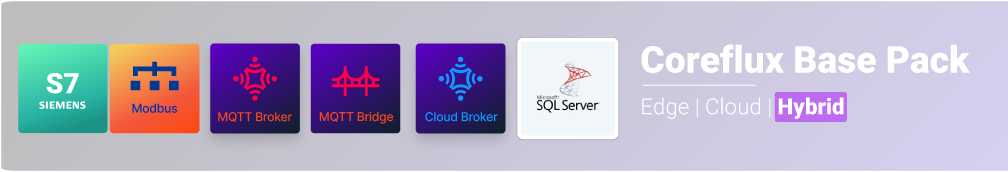

One simple Hub.

Free to download with a local broker out-of-the-box.

Energy Management is hard...

In today’s world, measuring and managing your energy inputs and outputs can make or break a business:

- Timing your productions with the schedules of lower energy cost.

- Optimizing internal energy production.

- Balance overall power costs.

These are all examples of key factors of energy efficiency solutions, regardless of what industry you're in.

We make it look easy:

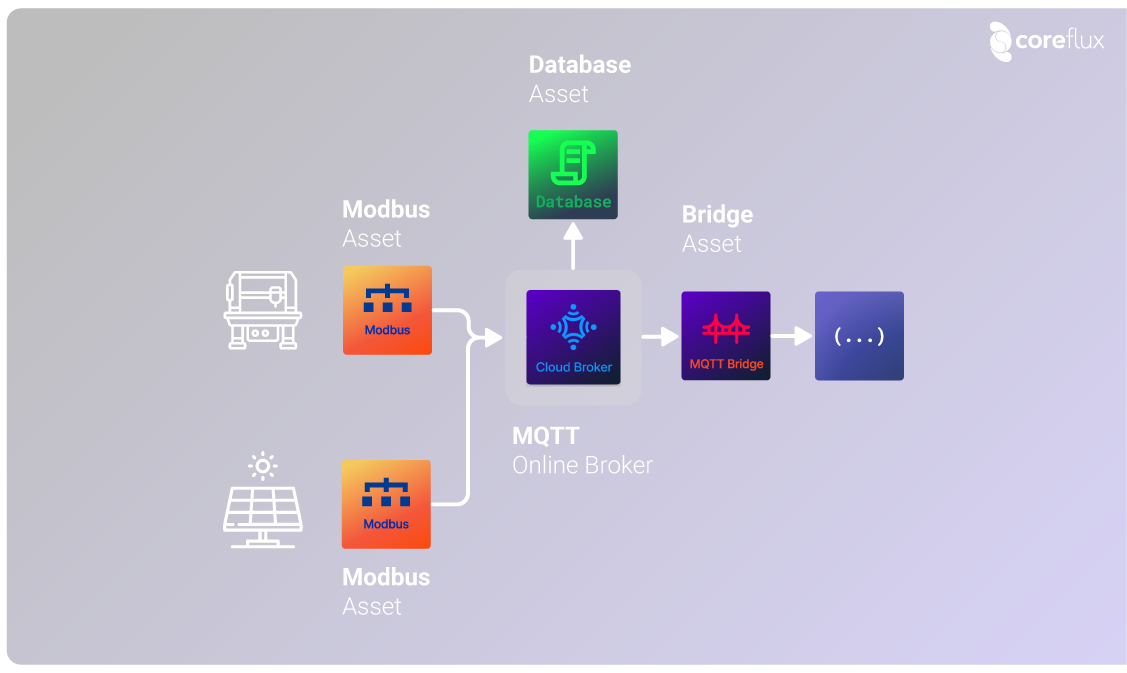

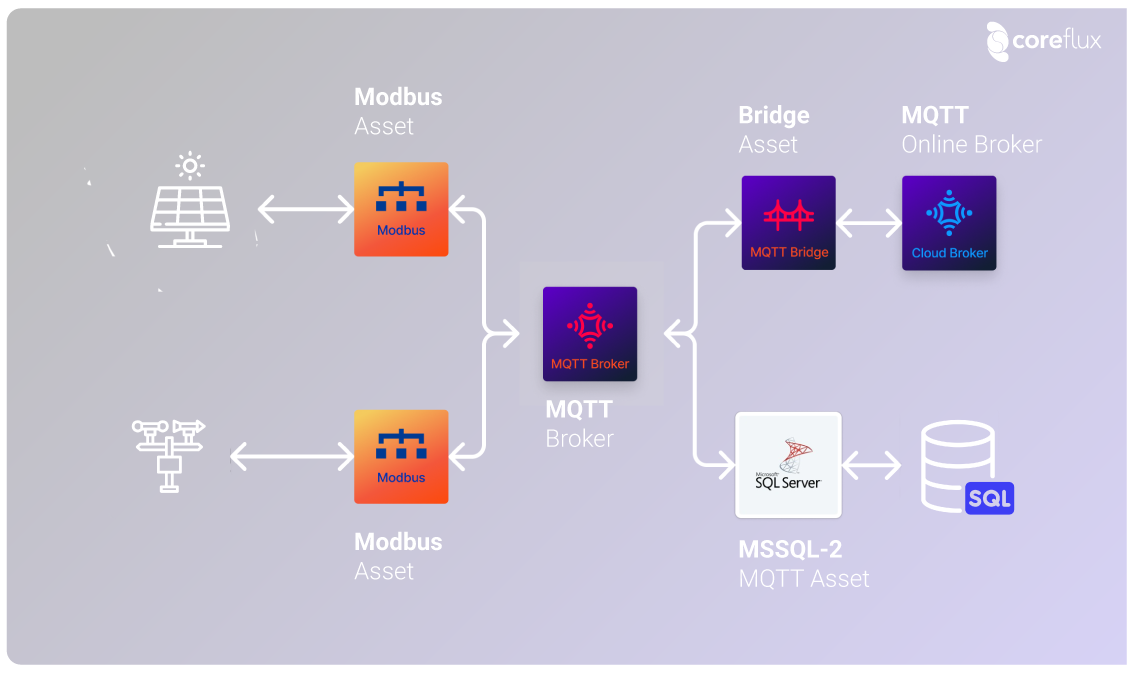

We start off with a small factory which, as an example, will be called “EnerManage LLC”.

It’s composed of one machine (energy output) and a solar panel (energy input).

Good news: this IIoT energy monitoring can be scaled to any size, both in terms of equipment and geographies, with little to no changes in the types of Flux Assets used.

Their equipment is outfitted with energy measurement devices, so the plant’s technical team can gather individual values from the corresponding electrical cabinets.

They chose devices that communicate through Modbus.

But the people over at “EnerManage LLC” want to work smarter, not harder:

STEP-BY-STEP

Real-Time Asset Tracking is hard...

Knowing where your products, people, vehicles and other logistic resources are, at any given time, provides your business with the edge required to:

- be competitive;

- create additional business opportunities;

- create value, for yourself and for your customers.

We make it look easy:

In the example depicted above, we’ll use “AssetTrack LLC” as a theoretical client.

This company has a series of assets on the move:

- Product being carried by forklifts (from batches to pallets)

- Movable equipment

- Transport for personnel (trucks, cars, etc).

The assets are equipped with 3rd-party tracking systems: RFID tags, triangulated by antennas spread across the warehouse (it could also be GPS or other).

STEP-BY-STEP

Remote Monitoring is hard...

When you supply machines to a customer, you focus on what you do best: the functionalities you have the most experience in developing.

But there is an entire new layer underneath the hardware: all the data your machine generates.

The value that can be extracted from it benefits both your company and your customer.

With the appropriate data, you can:

- Optimize production,

- Optimize the scheduling,

- Consult outcomes and delivery estimations, and more.

Empowering your bare metal and functionality with added data creates the potential for new data-driven business models.

We make it look easy:

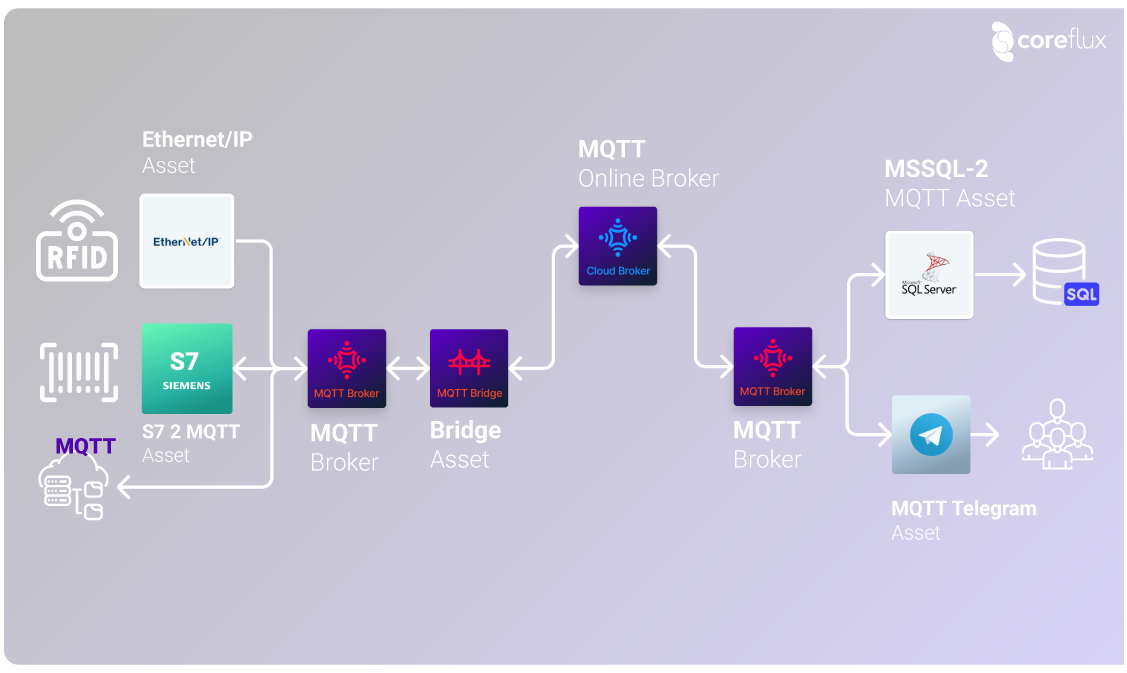

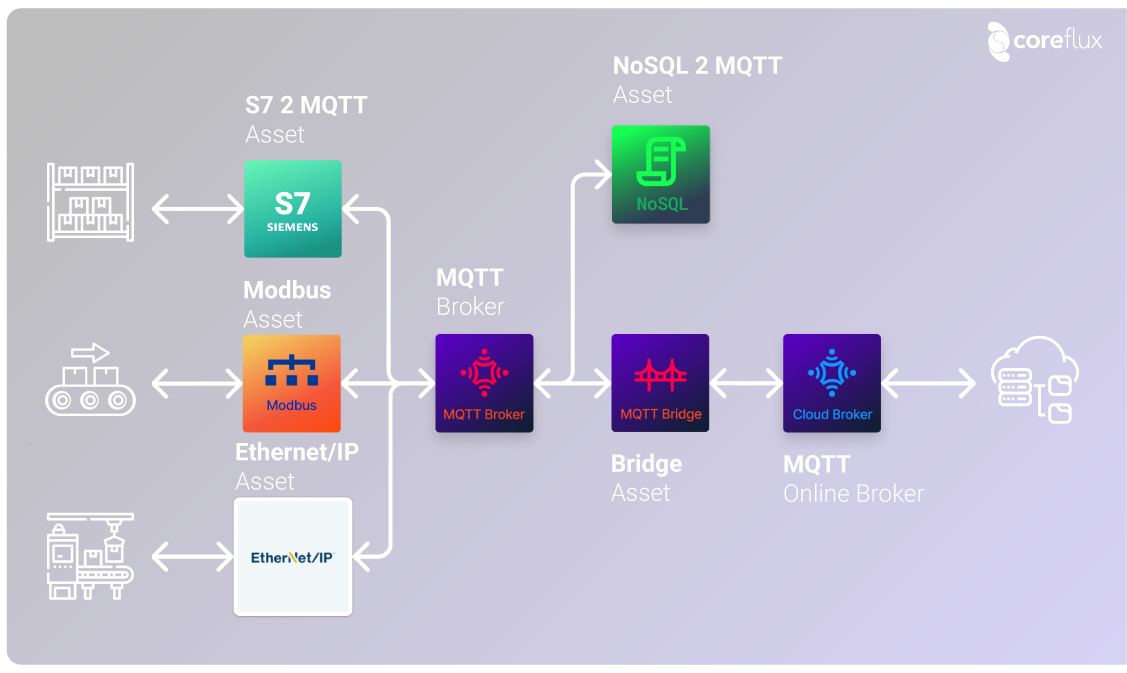

Imagine a machine supplier called “EfficiMonit LLC”.

Their machines receive some kind of input and process it into a desired output, across multiple stages of functioning.

When building their equipment, the folks at “EfficiMonit LLC” installed sensors for these sections.

For this example, we’ll only focus on:

- Retrieving PLC data from a Siemens S7 device and

- Gathering energy data from a Modbus-enabled device.

A lot more could potentially be gathered.

STEP-BY-STEP

Performance Optimization is hard...

In scalable renewable energy facilities, like a solar park, it is essential to verify in real-time how each equipment is performing.

If something is outside expected values, teams on standby must be notified automatically and respond immediately.

Such is the power of sustainable energy with IIoT.

We make it look easy:

Let’s take the example above, to which we’ll give the example name of “PerformOptim LLC”. This company is running a solar park composed of one or more strings of solar panels.

They aim to implement automated energy systems so they can benefit from:

- energy data analytics;

- predictive maintenance in energy;

- energy storage optimization.

STEP-BY-STEP

Automated Route Optimization is hard...

When a company is moving goods, it is vital that the route is as optimized as possible, from small distances (inside a warehouse) to large distances (across continents).

This will ensure the vitality of the business, in terms of:

- time to delivery;

- transportation costs;

- quality of perishable goods.

Your best bet? To embrace the Industrial Internet of Things.

We make it look easy:

In this use case, let’s consider “RouteOptim LLC” as an example company.

They require small logistics for moving batches of goods within the company, into and out of warehouses.

“RouteOptim LLC” uses “First In First Out” (FIFO) logic, as the duration of the goods is time sensitive.

As a location system, they’re gathering position data from RFID tags. They are triangulated by local antennas, which route this data to a local machine.

STEP-BY-STEP

Production Optimization is hard...

Do you despise the word “idle”?

For a manufacturing business (and well, any other kind of business) there is nothing worse than having machines standing by and not actually producing.

For this reason, it is fundamental that production is always scheduled and going continuously.

We make it look easy:

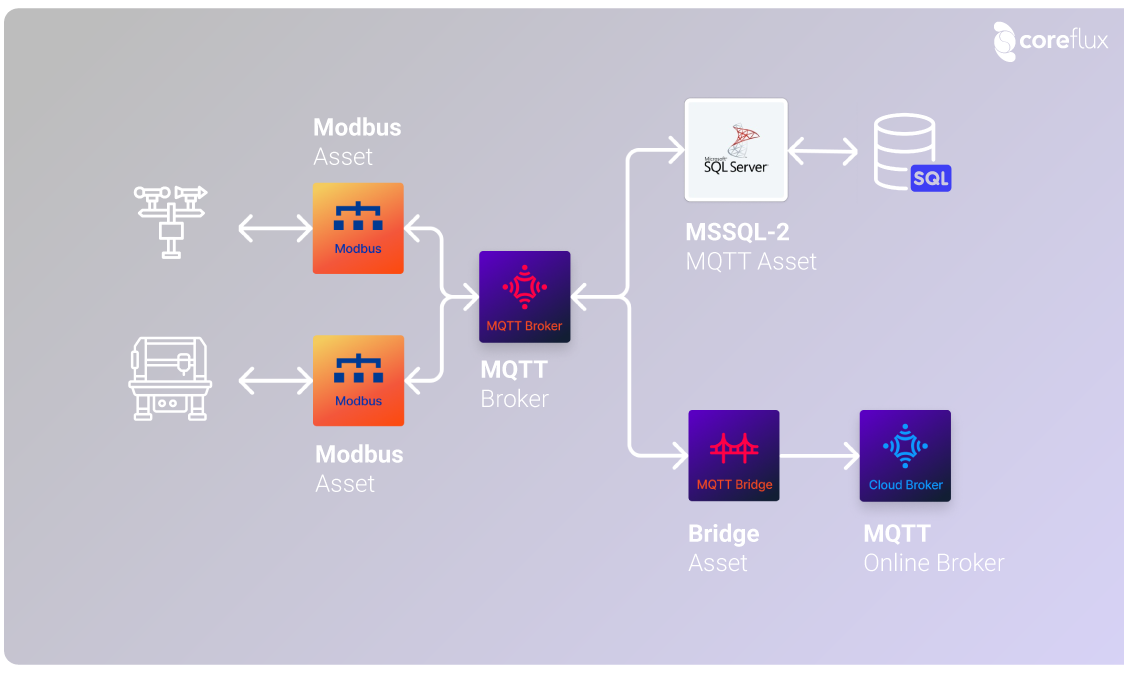

Let’s look at “ProdOptim LLC”. This company runs a cardboard box assembly line.

For the business to be profitable, it is essential that they:

- Respond to orders in time;

- Avoid backlogs

- Avoid downtimes of any kind.

STEP-BY-STEP

Grid Integration is hard...

Energy is shifting. From the hands of large corporations, into the grasp of small residential and retail producers.

In several countries, legislations for energy communities are maturing.

This leads to an increase of production units on rooftops, both in urban and rural areas.

The challenge: seamless integration between the grid at large and the local units.

There are benefits in real-time information being handed to both parties.

We make it look easy:

Picture a company called “NetGration LLC”.

Their purpose is, as described, to link local small energy production units into the network.

The digital transformation journey begins with gathering data from the devices installed in the clients’ rooftops.

Here’s how Coreflux realizes the promise of smart grid technology:

STEP-BY-STEP

Warehouse Management is hard...

Managing a warehouse facility in terms of space and movement efficiency is fundamental to ensure logistics and delivery time in a business environment.

Embracing the value proposition of Industrial IoT can make this process a lot more efficient.

We make it look easy:

For this use case, let’s consider an example company called “WareManage LLC”.

They produce parts in CNC machines, which are then transported to a warehouse.

This warehouse needs to be well organized to store parts with different shapes and sizes.

STEP-BY-STEP

Productive Energy Consumption is hard...

Consuming energy is easy... Too easy, even.

But:

- measuring what your machines are expending at each moment of their process;

- being able to provide that information to your customers;

- so that they may ensure that power is used in the most optimized way possible, and;

- maximize the gain they make from what your equipments help them produce...

That’s most certainly not a walk in the park.

But it’s worth it!

And the good news is that Coreflux let's you achieve this in a simpler way.

We make it look easy:

Let’s look at “ProEnerCons LLC”.

This company manufactures plastic extruders that allow their clients to produce plastic pieces for the medical industry.

For their clients' business to be profitable, it is essential to:

- Deploy machines that are energetically transparent (both efficient and detailed);

- Avoid backlogs;

- Avoid downtimes of any kind.

STEP-BY-STEP