Real-time Asset Tracking

in Logistics

Use Case #02

Hello there.

If you work in Logistics, you may have noticed that transitioning to the standard of the Industry 4.0 is hard.

It's no small task to Digitalize and Integrate all sorts of literally moving targets when your goal is to effectively track your assets in real-time.

Let alone retrieve meaningful data from that process and uncover actionable insights, that lead to the pot of gold at the end of the rainbow that is "optimization".

Let us show you how you can make it look easy by applying the Coreflux method by reading more or watching the video below:

1) Assemble and configure Coreflux Assets as the Building Blocks of our system;

2) Centralize the information in a Database;

3) Attribute Recipes to achieve the desired outcomes.

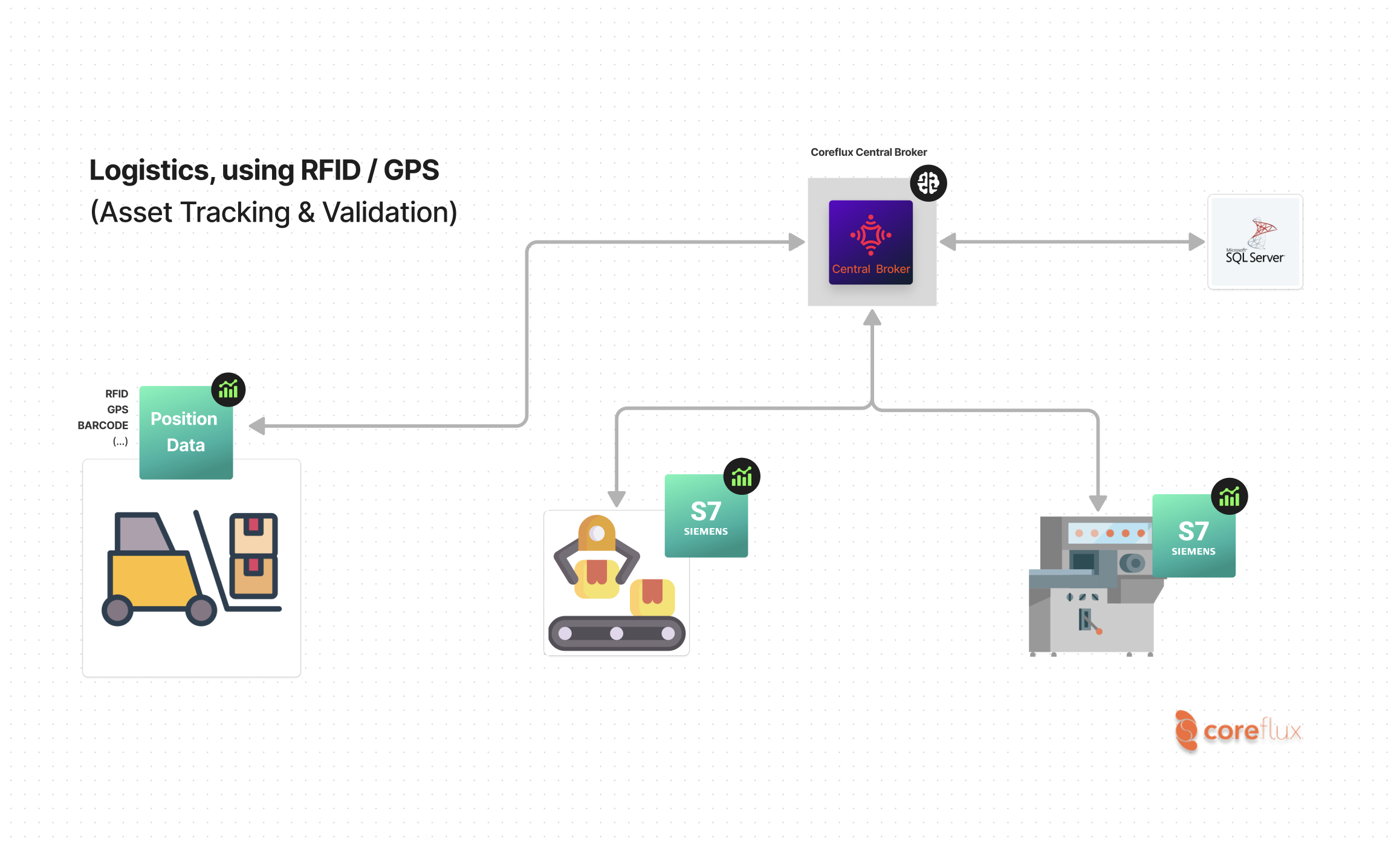

In this Use Case, we'll refer to an Asset Tracking system that relies on Barcode Scanning.

They are automatically generated, and we can consult them in a central database.

It will inform our Logistics system, our conveyor belt system, and the rules we set up in the database will redirect each material that needs to go to which area, via the specific conveyors that we prefer.

Afterwards, we'll re-check the Barcodes against an SQL Database, so we can feed a Recipe associated with that barcode back into the machine.

In turn, the machine will return the set point for that specific article that we're going to implement.

Ready?

Go.

Step 1: Integration

Let's begin on the PLC side for all things Logistic.

For tracking the material, we can monitor the result here, fed from the Database.

Here we can check the output value.

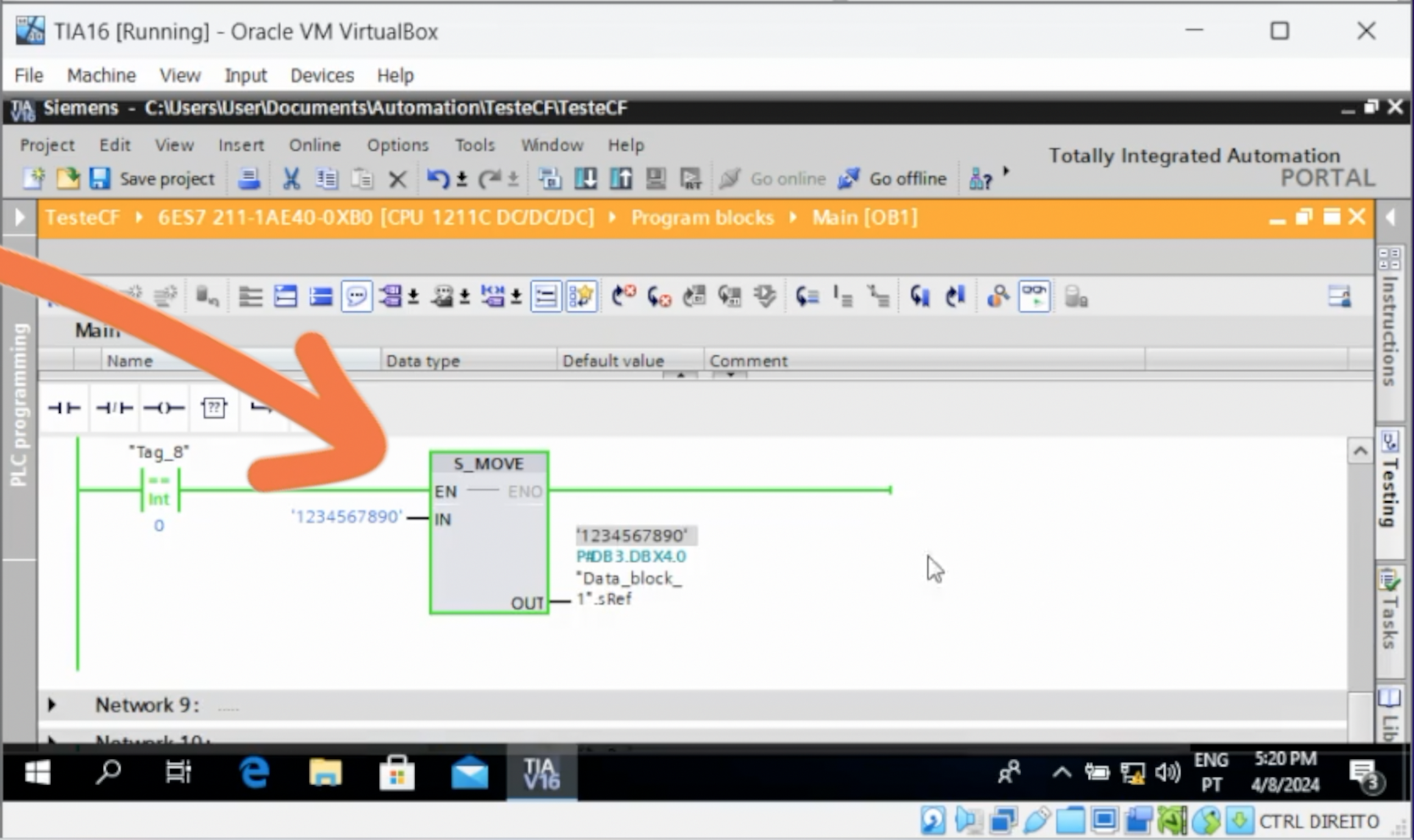

And this represents the automatic barcode generation.

This is where Coreflux comes in

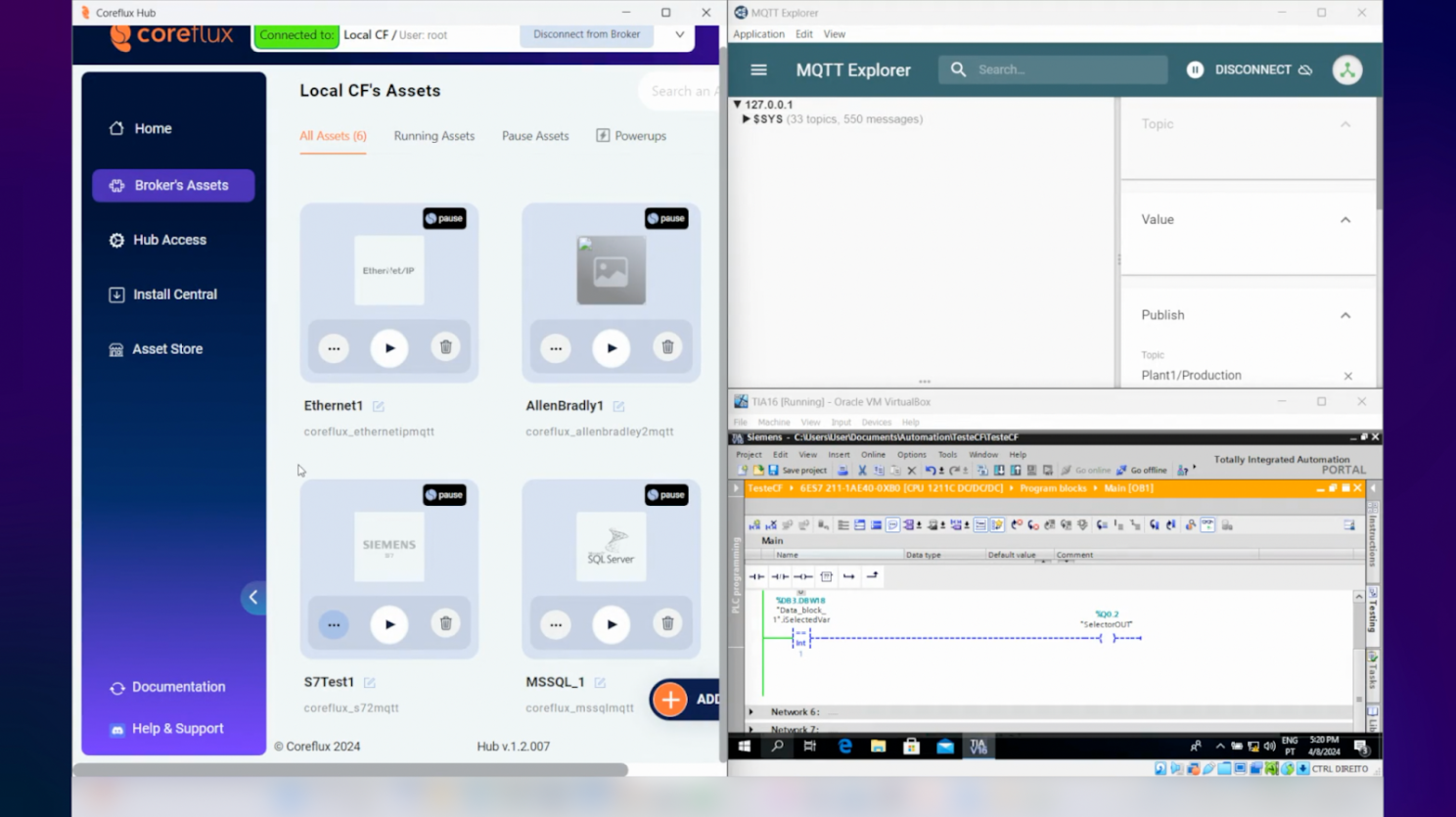

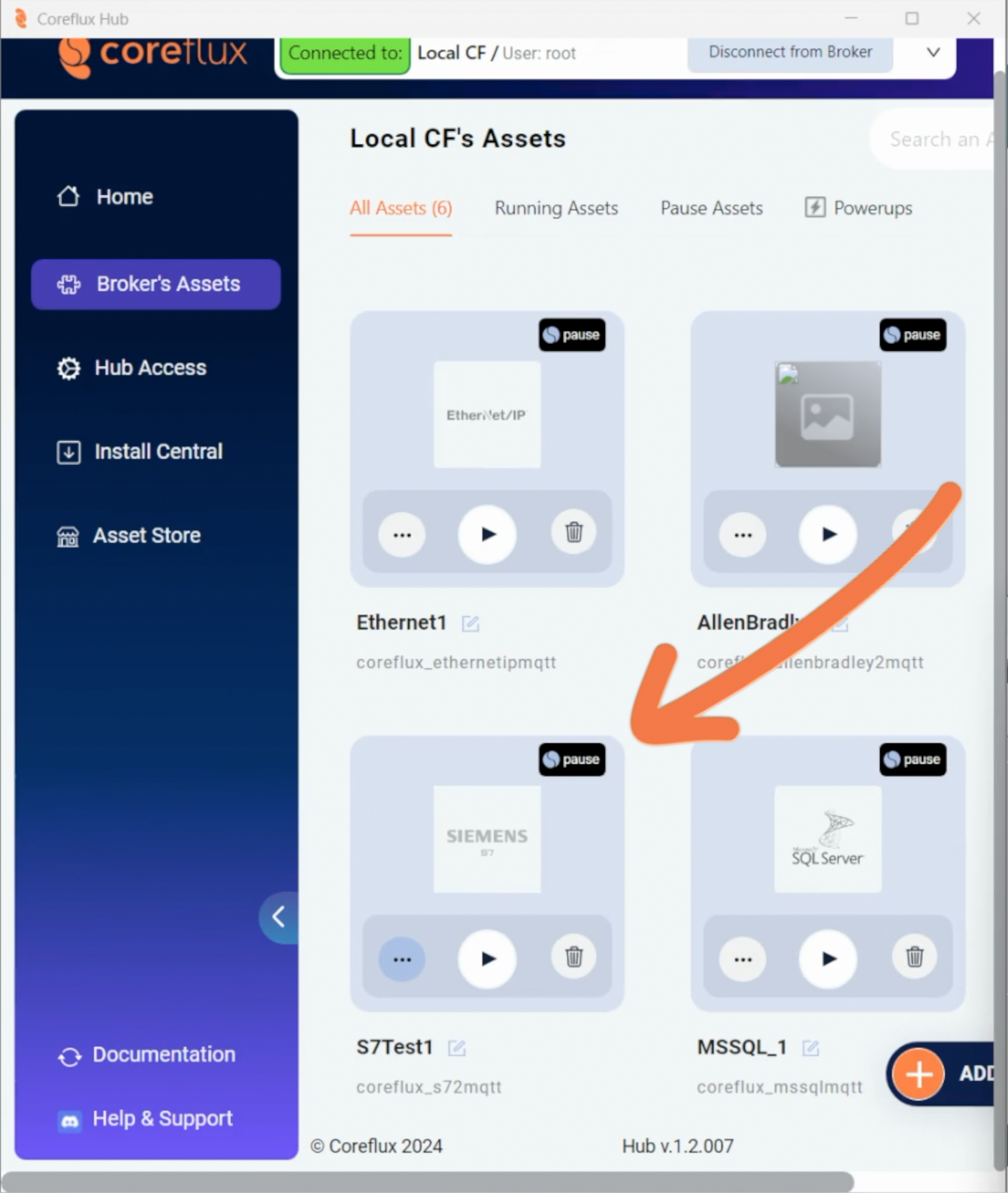

Download the Coreflux Hub and install a local broker for free.

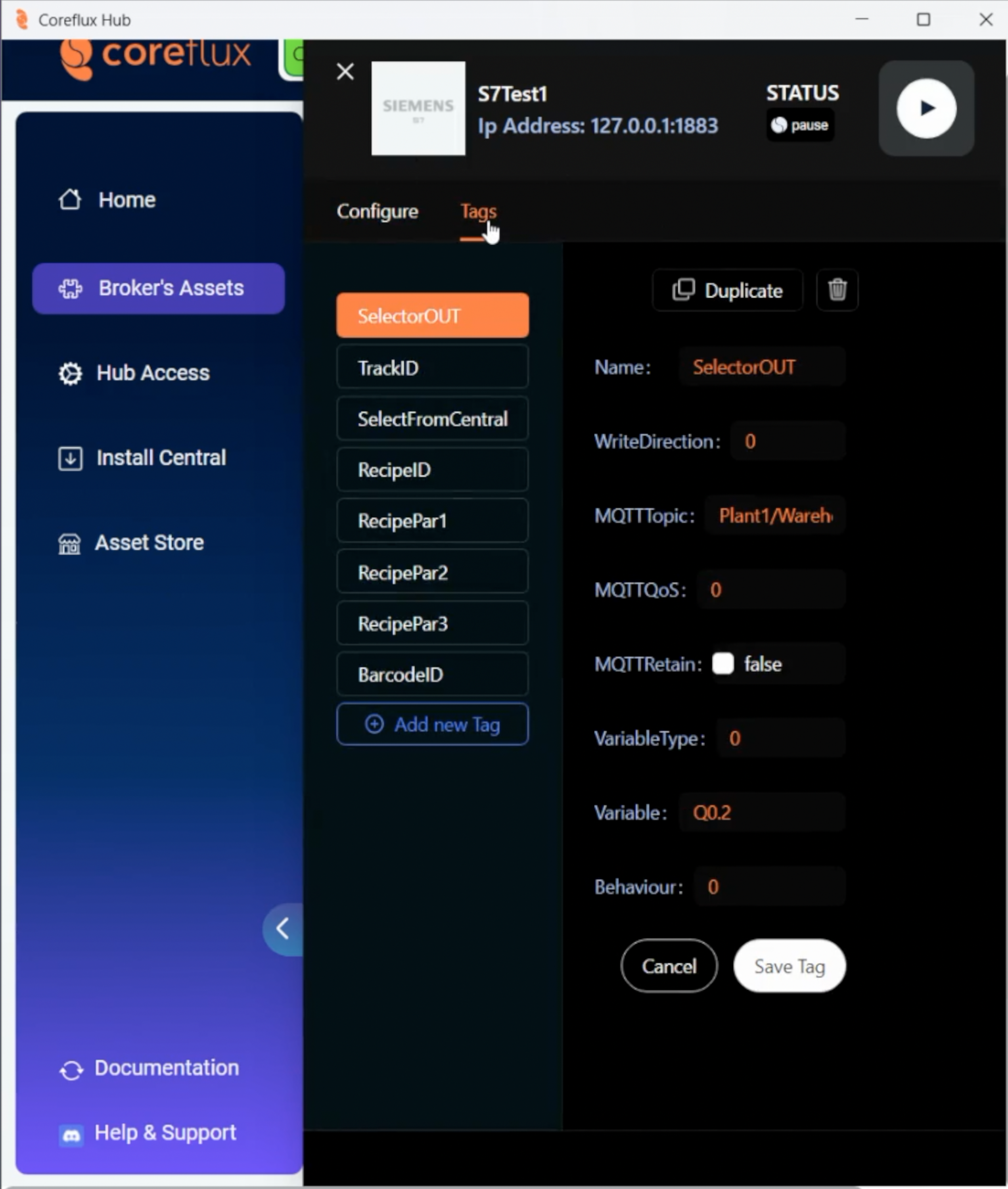

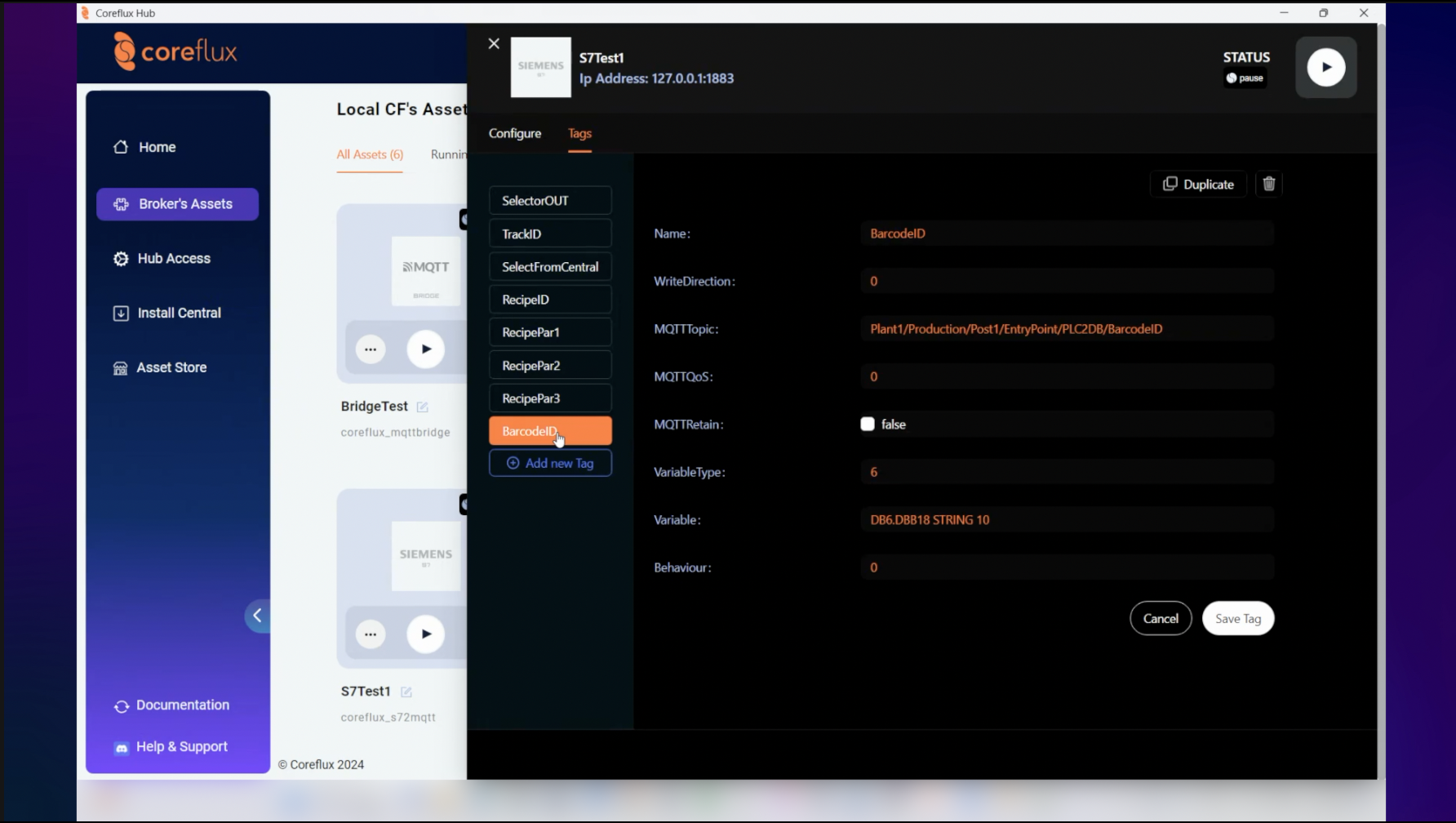

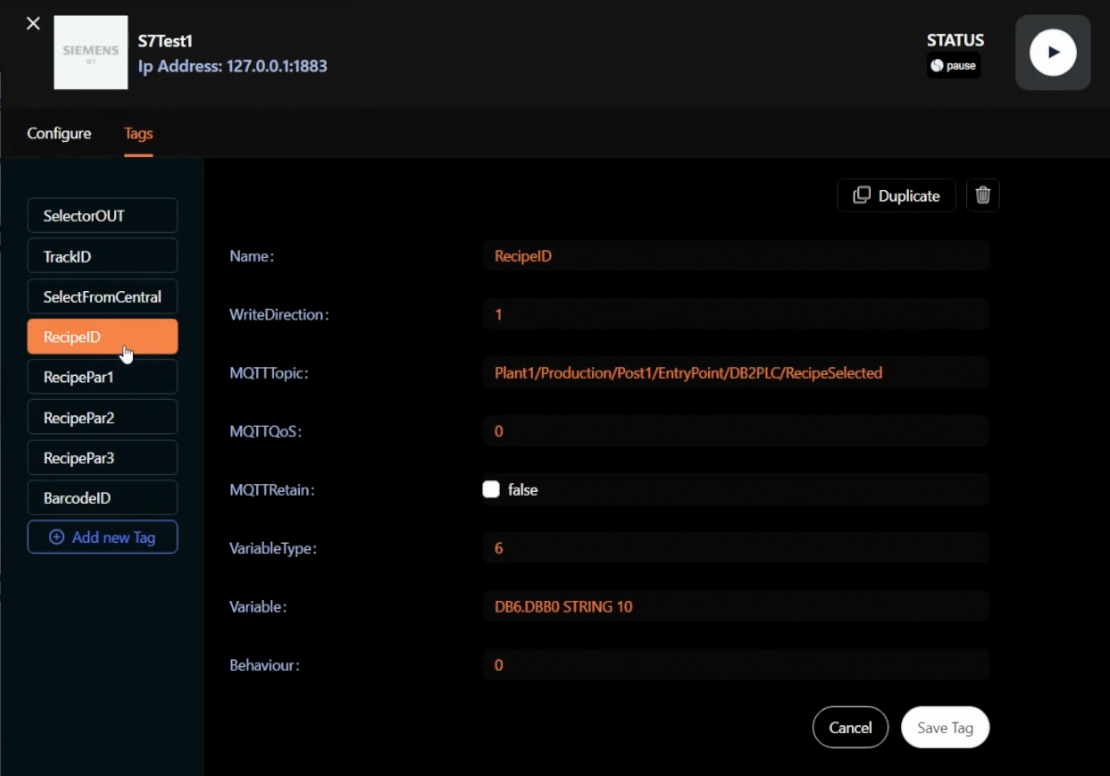

Now, let's look at our first S7 Asset in the Coreflux Hub.

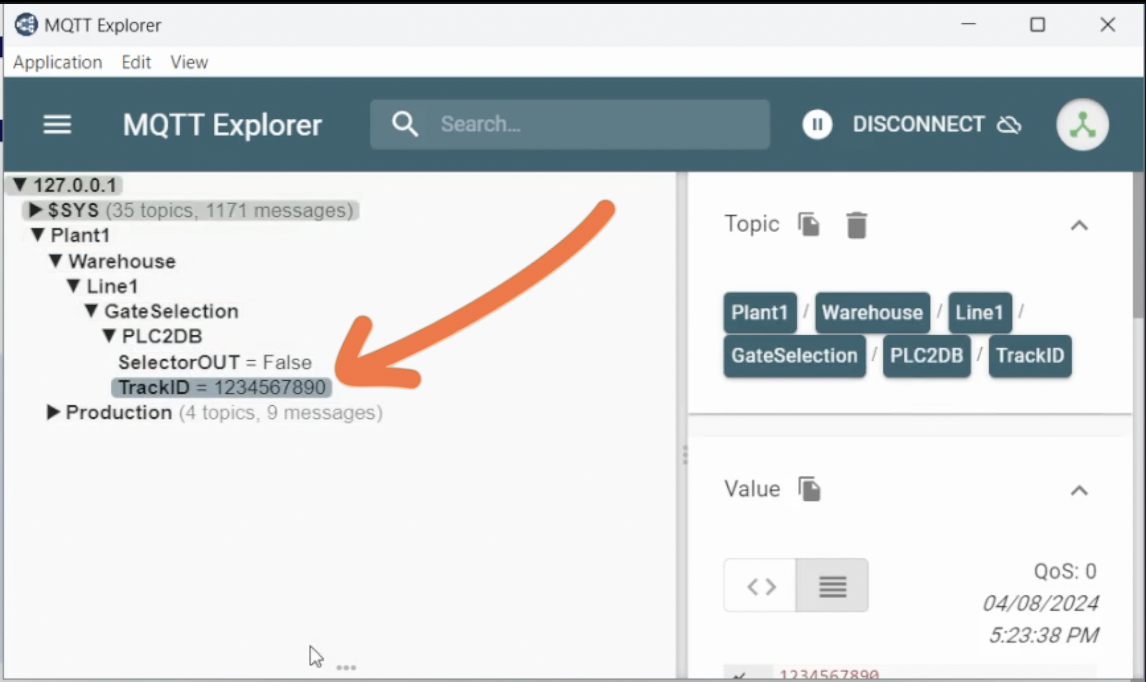

Check that the configuration is fully set up. And the tags too:

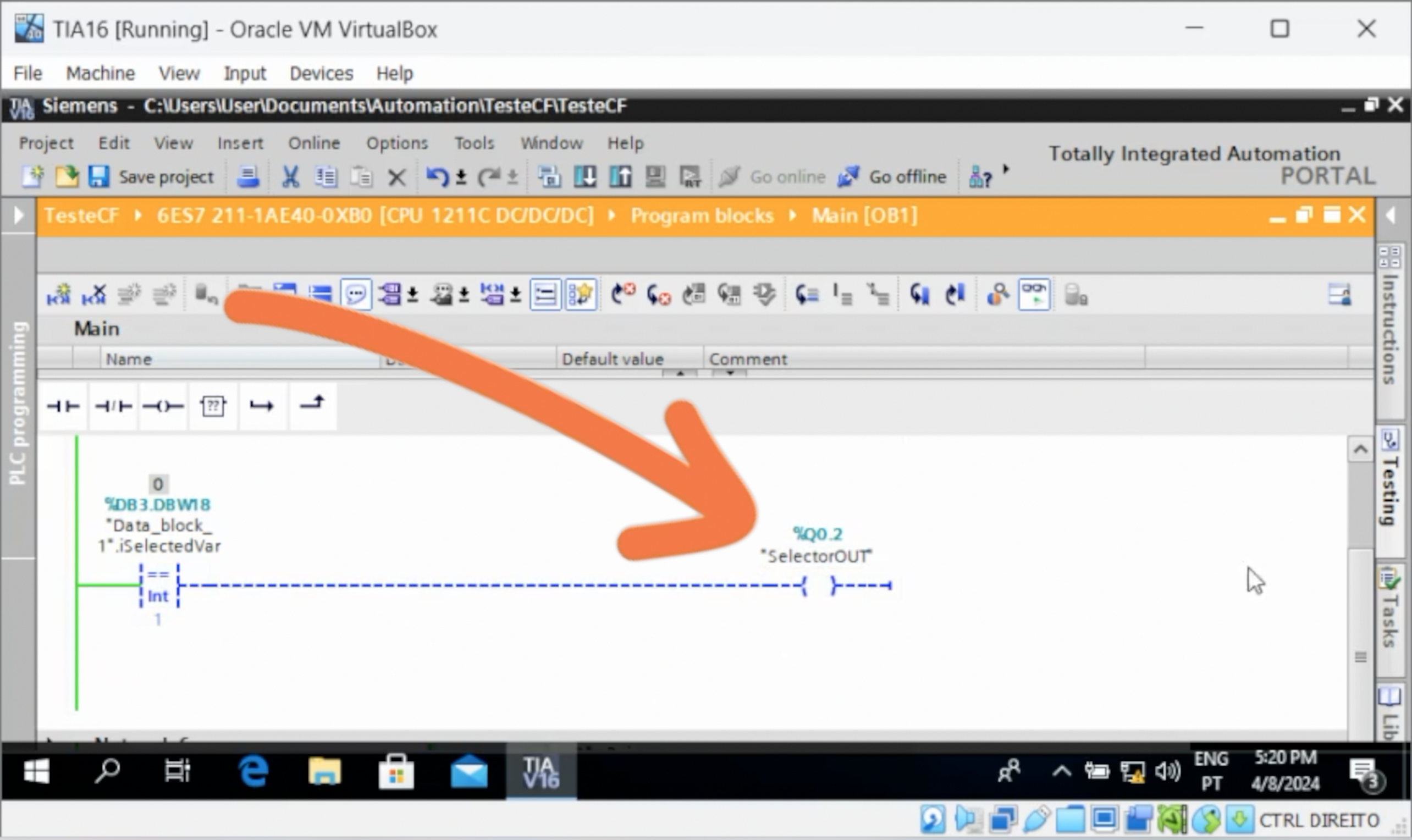

Start with the Select Output. This is how the PLC confirms the output that's being tracked.

Then, the Track ID is the barcode being read on the PLC side.

And finally, Select From Central is the result that we're going to consult from the database and feed back into the PLC accordingly.

These topics are important because we're also going to use them in the SQL Database Asset.

This is how we generate the corresponding triggers.

If we go into those Tags, you can see:

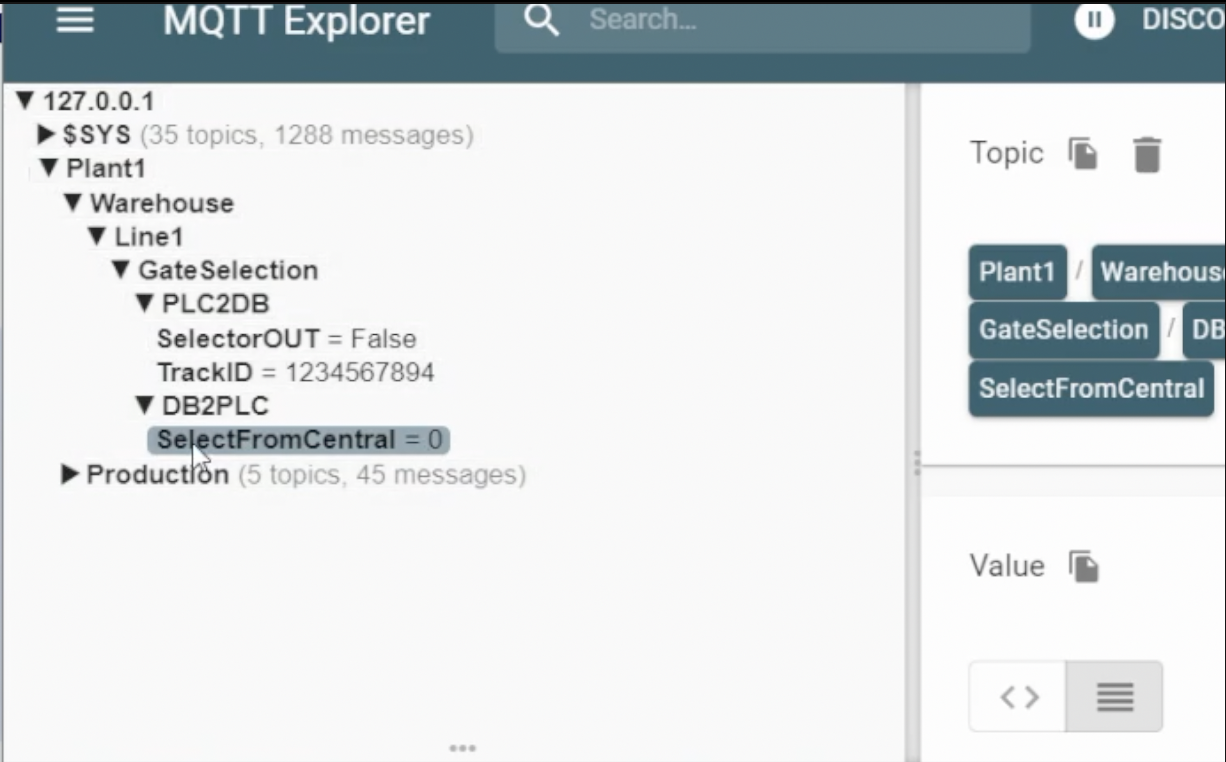

The Gate Selection, where the Trigger Topic is TrackID

And the Feedback Topic is SelectFromCentral

Which you can see in the query, fetching the value from the Database.

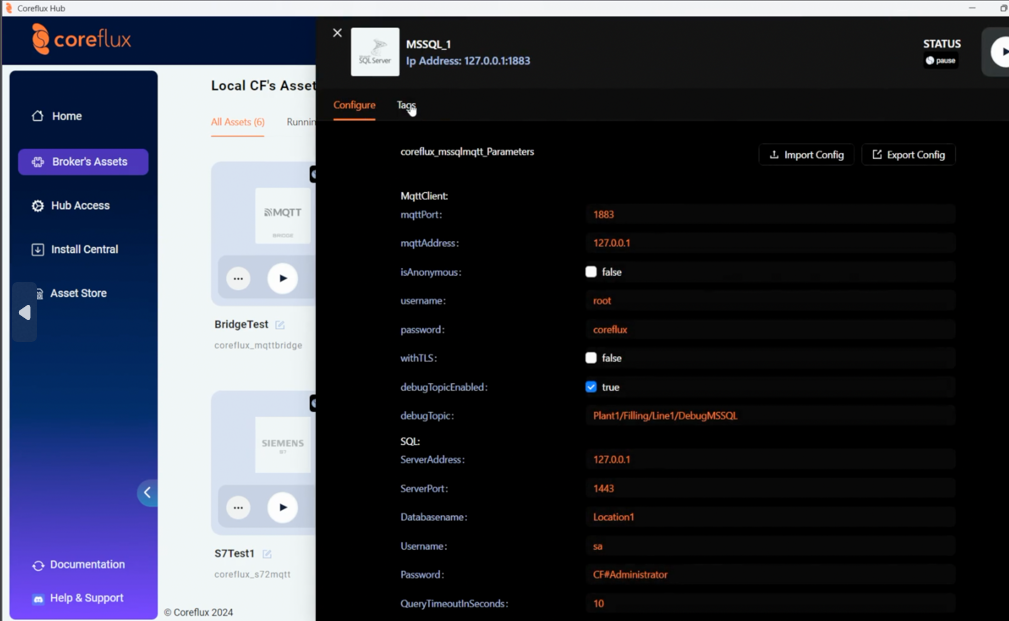

Speaking of Database

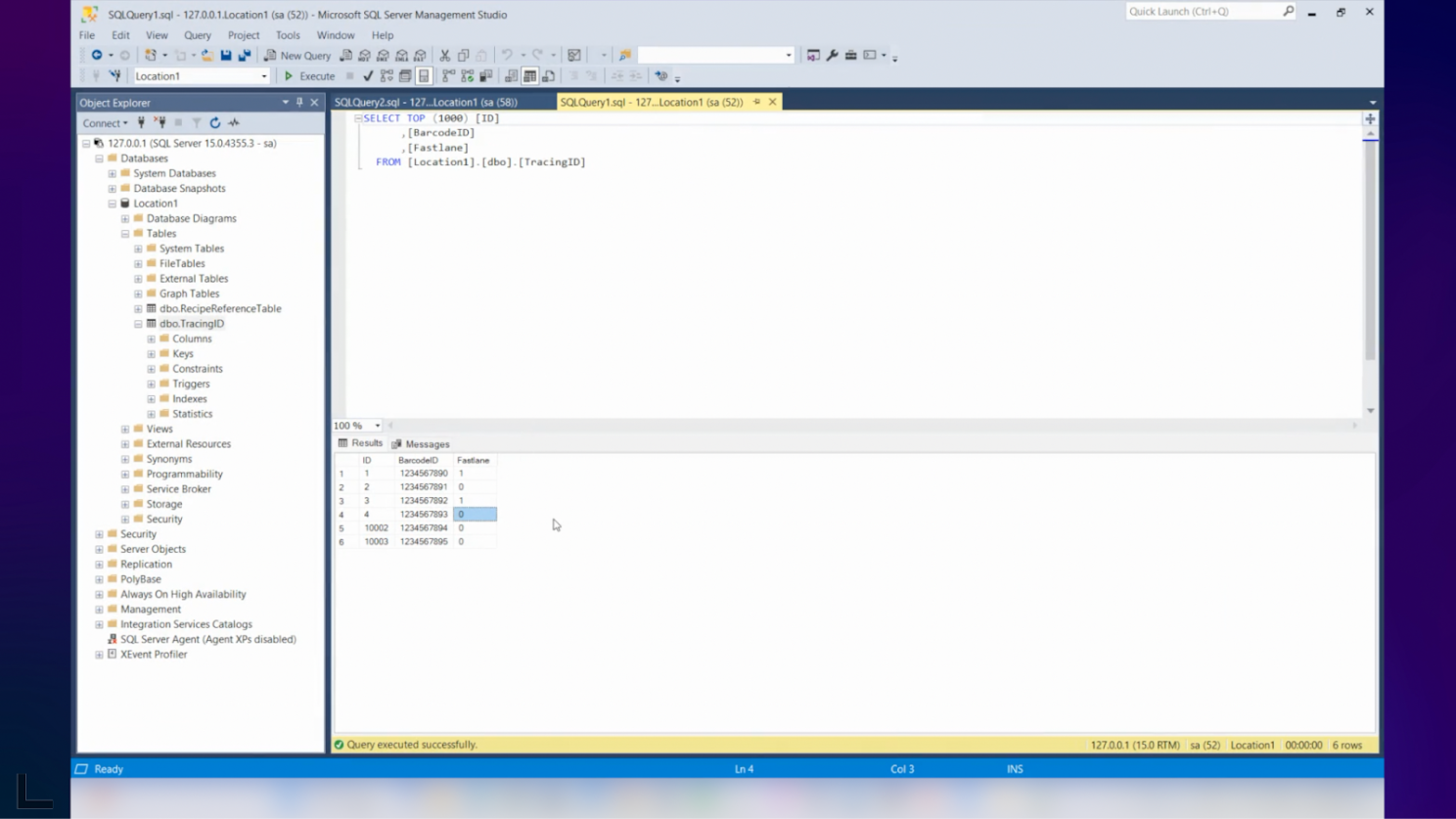

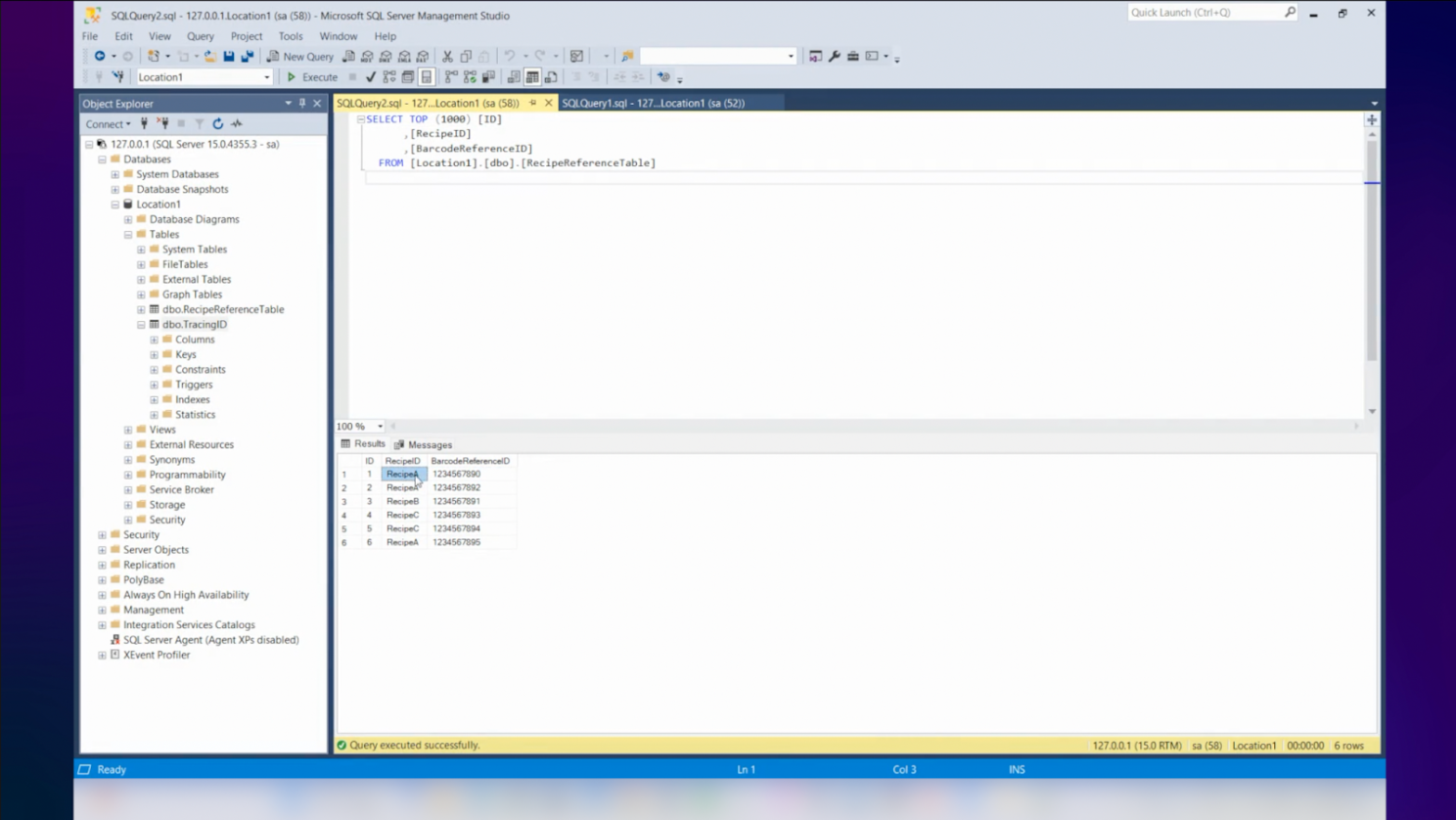

In the Database, we have a simple table with the corresponding Barcode IDs and the value for what we want to redirect on the conveyor system.

If true it shifts to one side, false it shifts to another.

Let's get this show on the road and activate this S7 Asset.

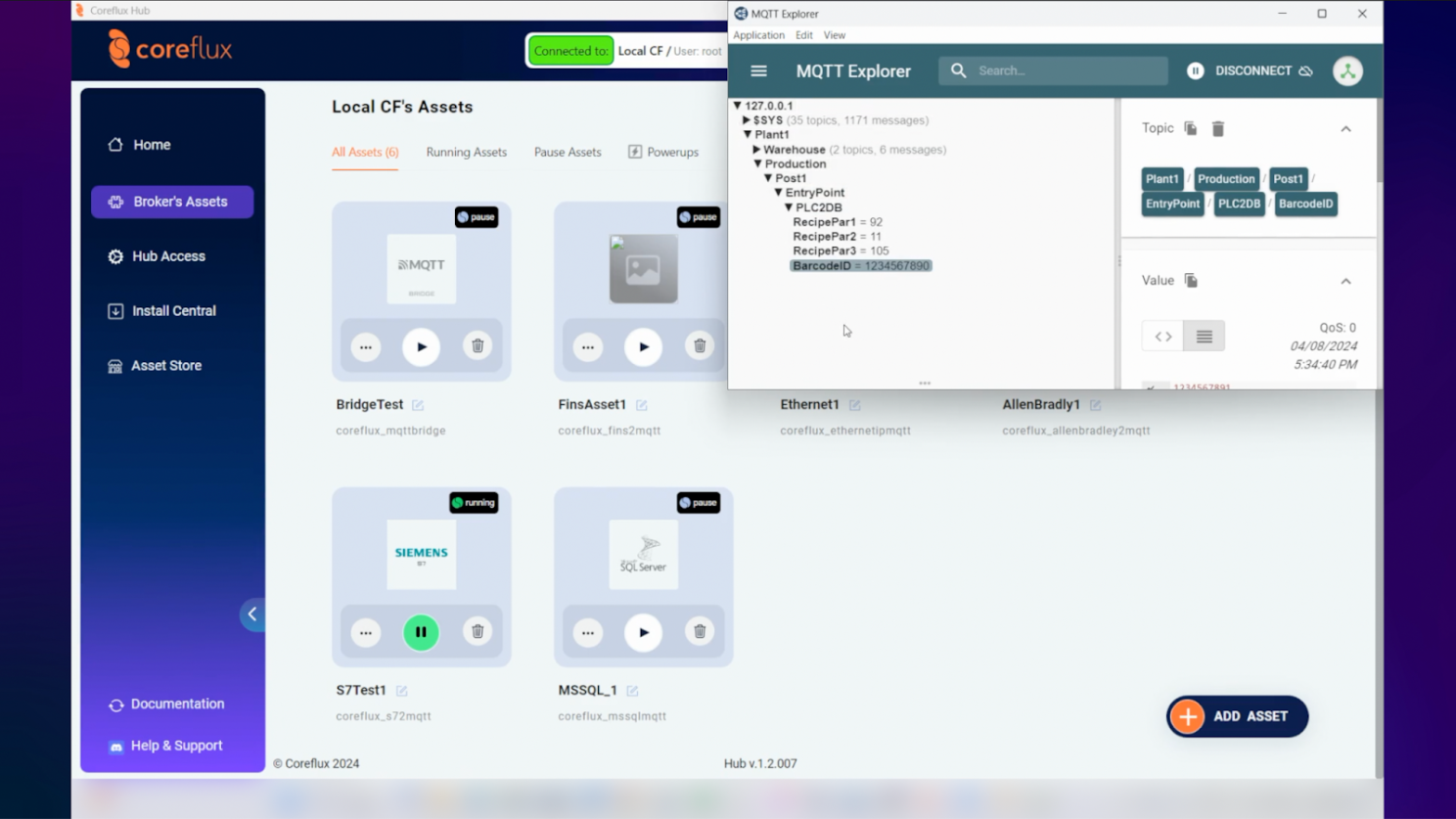

On MQTT Explorer we can see the information flowing from the PLC.

The Track ID is updating automatically, but there's no result on the PLC side yet.

So it's time to turn on the MSSQL Asset and re-check.

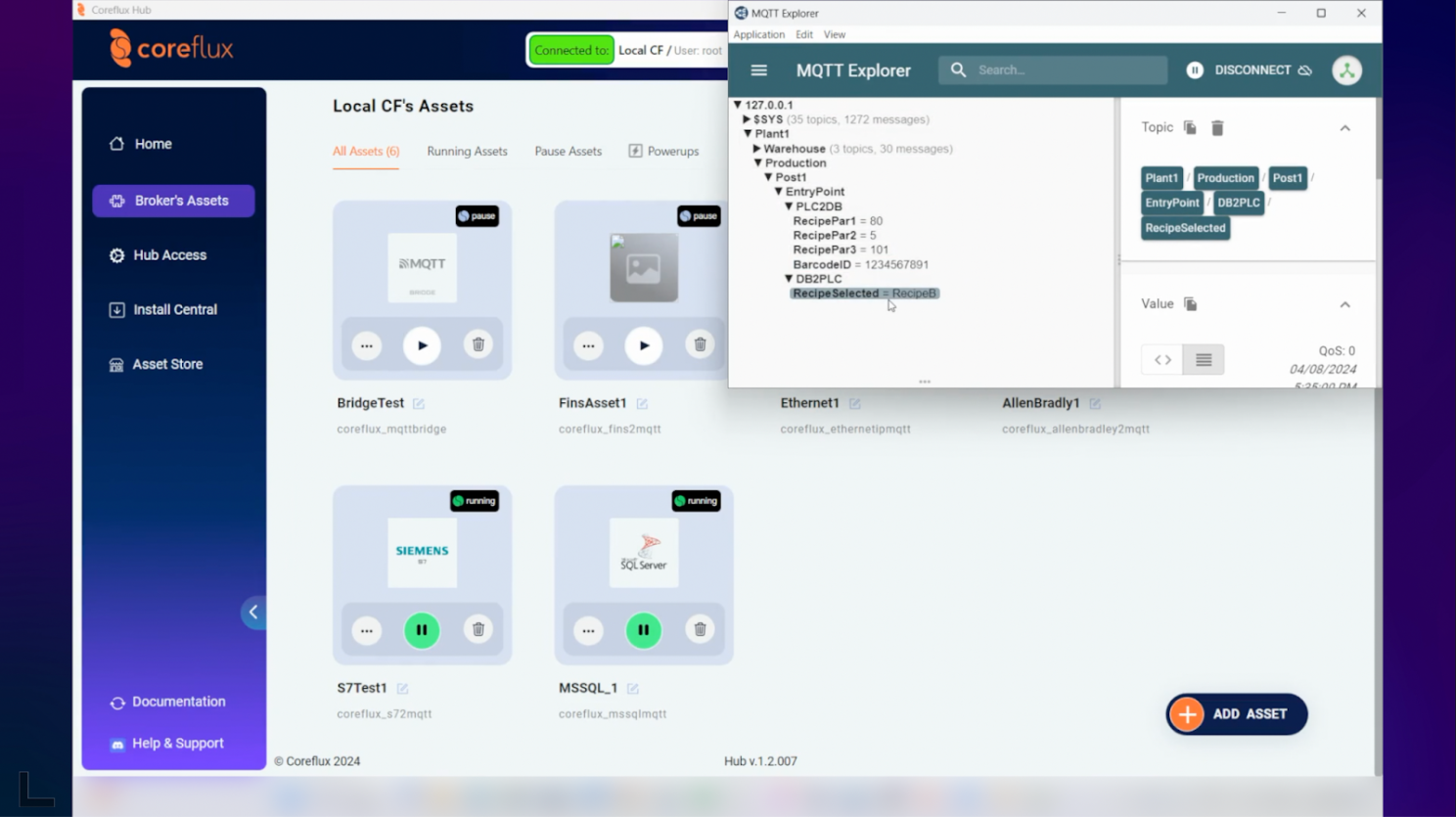

Now we can see the results coming from the Database and feeding the PLC.

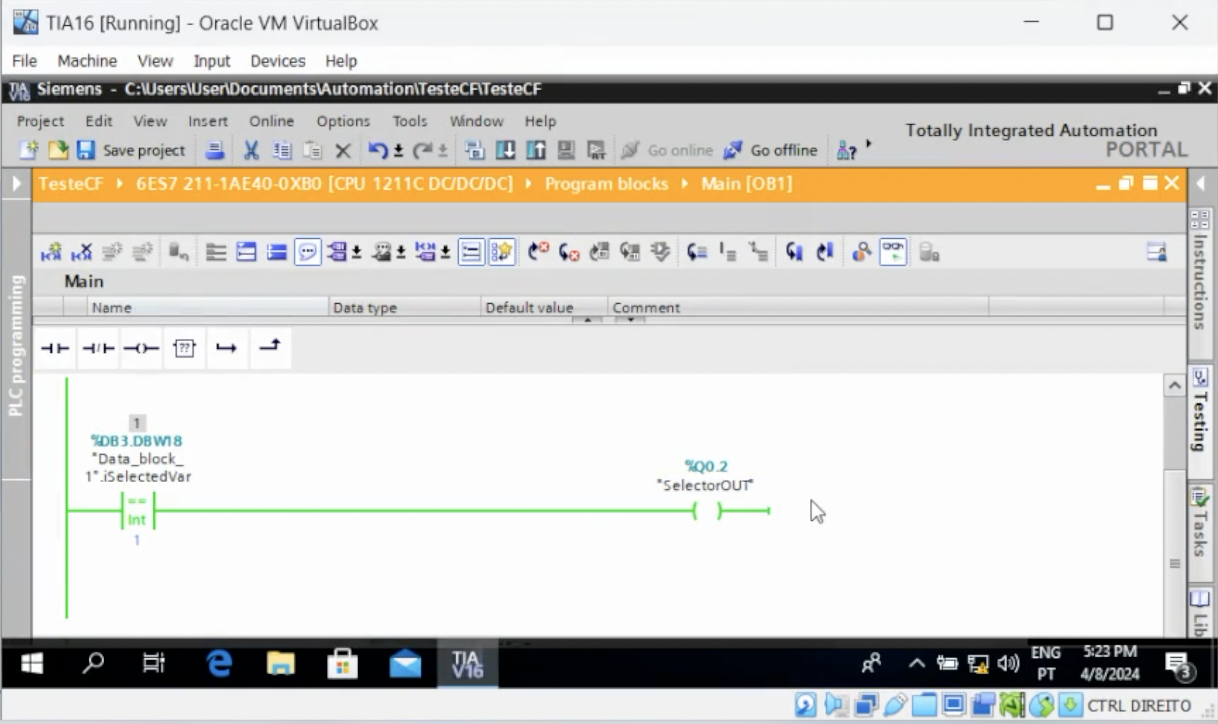

And if we go into the PLC software, we can see the output of the PLC is triggering the corresponding selector of the configuration we want to use.

Step 2: the Recipes

Now, it's time to make something we'll call a Material Selection Recipe.

We'll use a different database, where we have the relation between barcodes and their recipes, and we'll use the PLC for its connectivity.

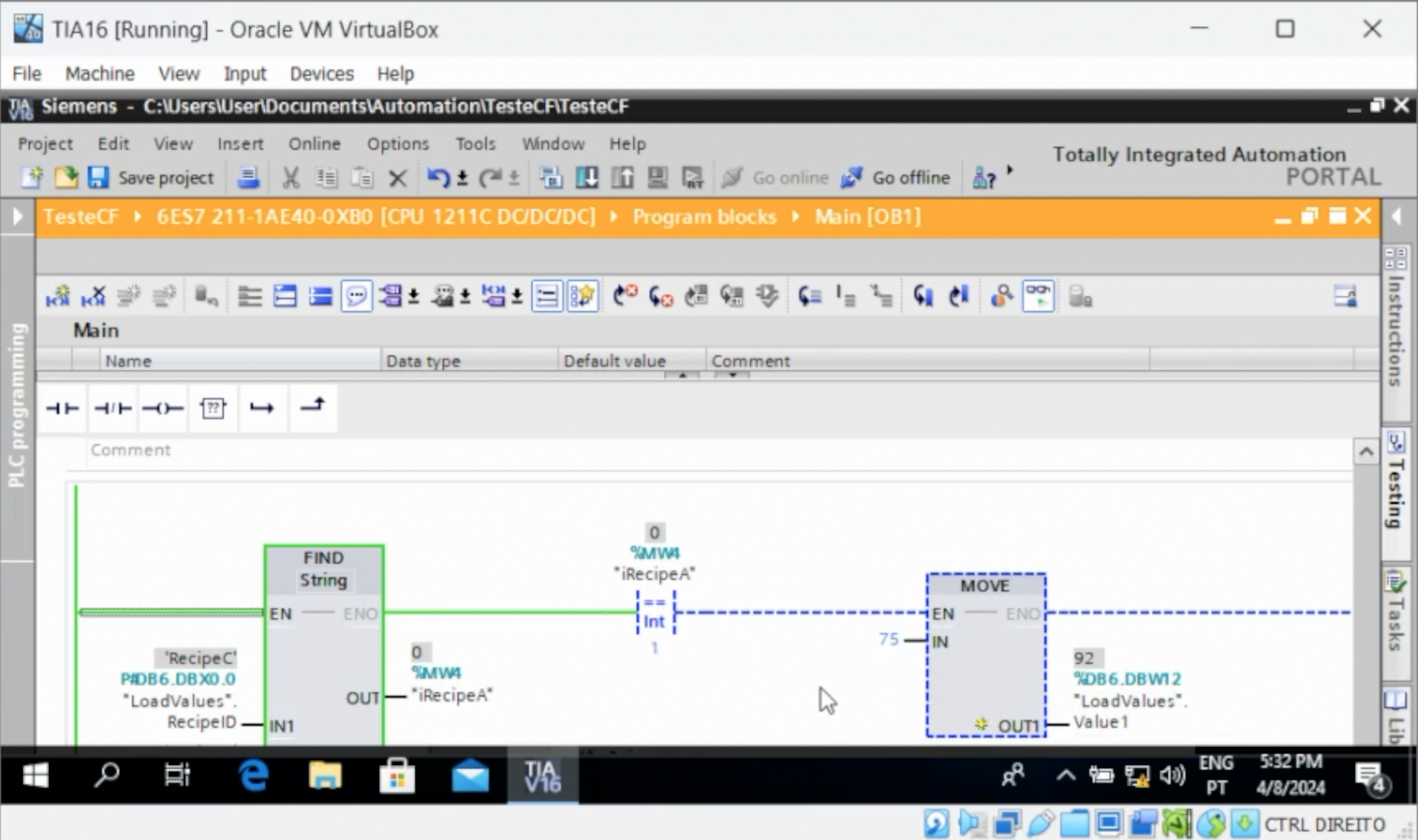

Here we can monitor the recipe it's getting from the Database, compare it against a local identification, and automatically load the corresponding parameters that we want.

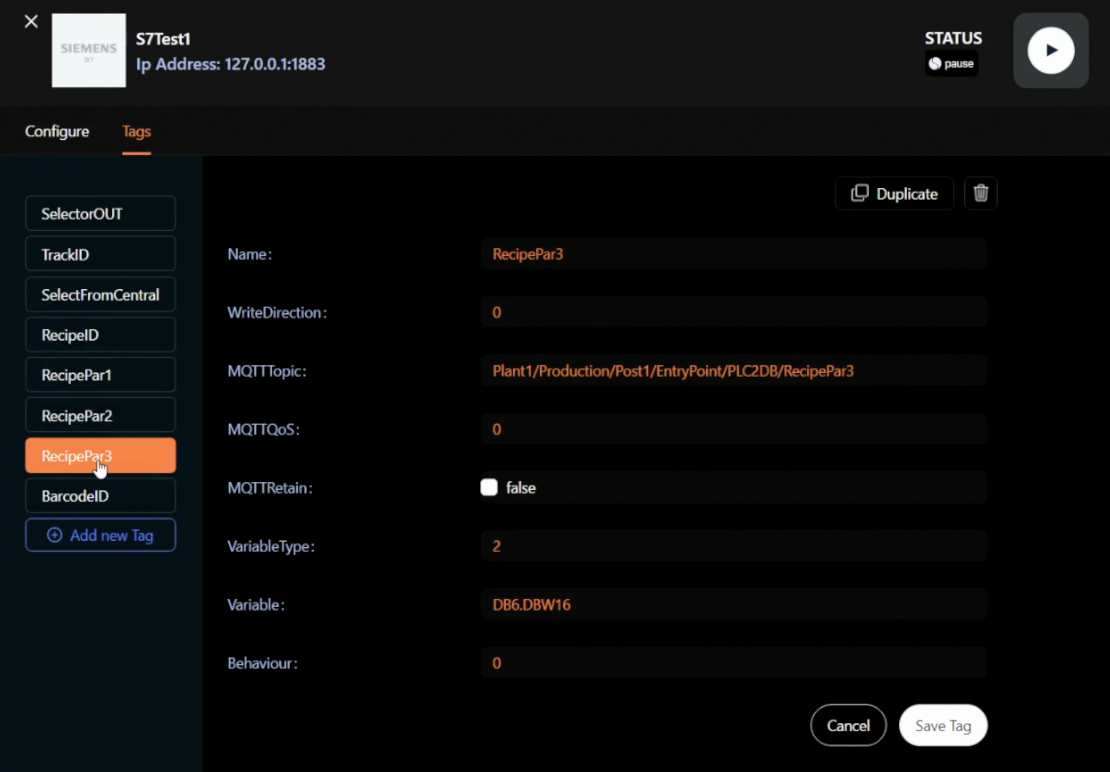

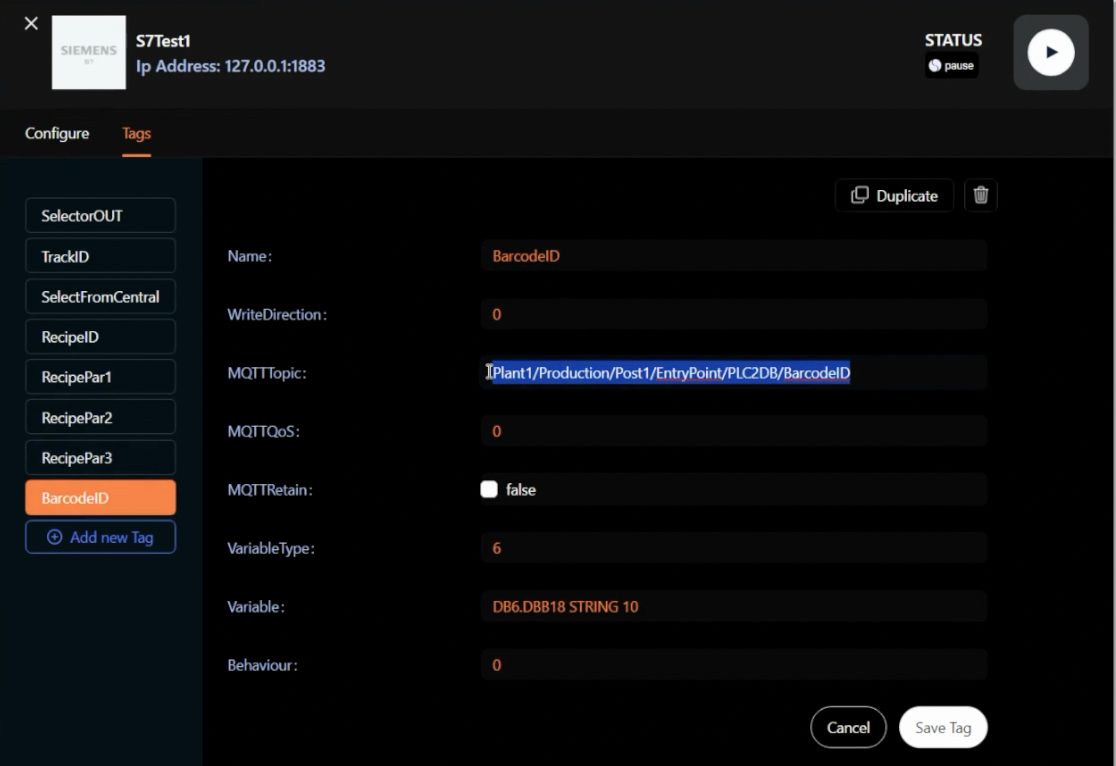

Let's play Tag

In the Asset for this PLC, we have a Tag that monitors the Barcode that identifies the article we want to check.

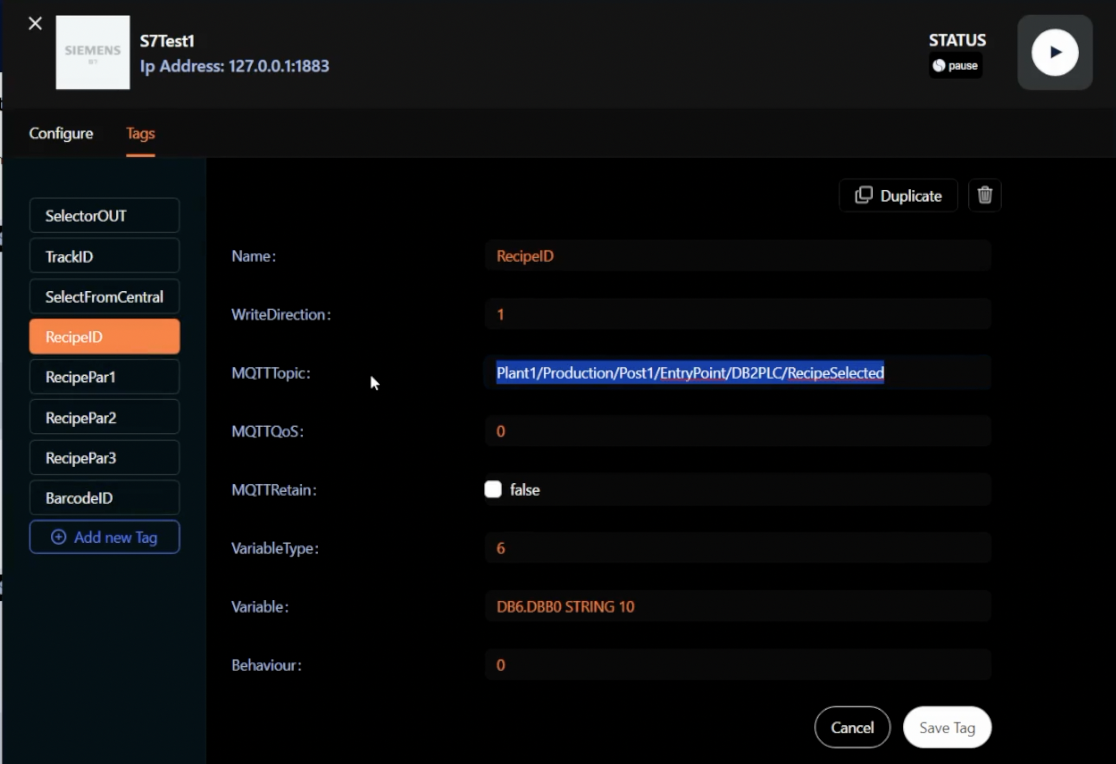

Then, it will feed the Recipe ID to the PLC coming from the database on this topic.

Also, it will monitor if the parameters in this Recipe are updating.

And we use the corresponding Topic for the Recipe to feed the PLC with the result from our Database.

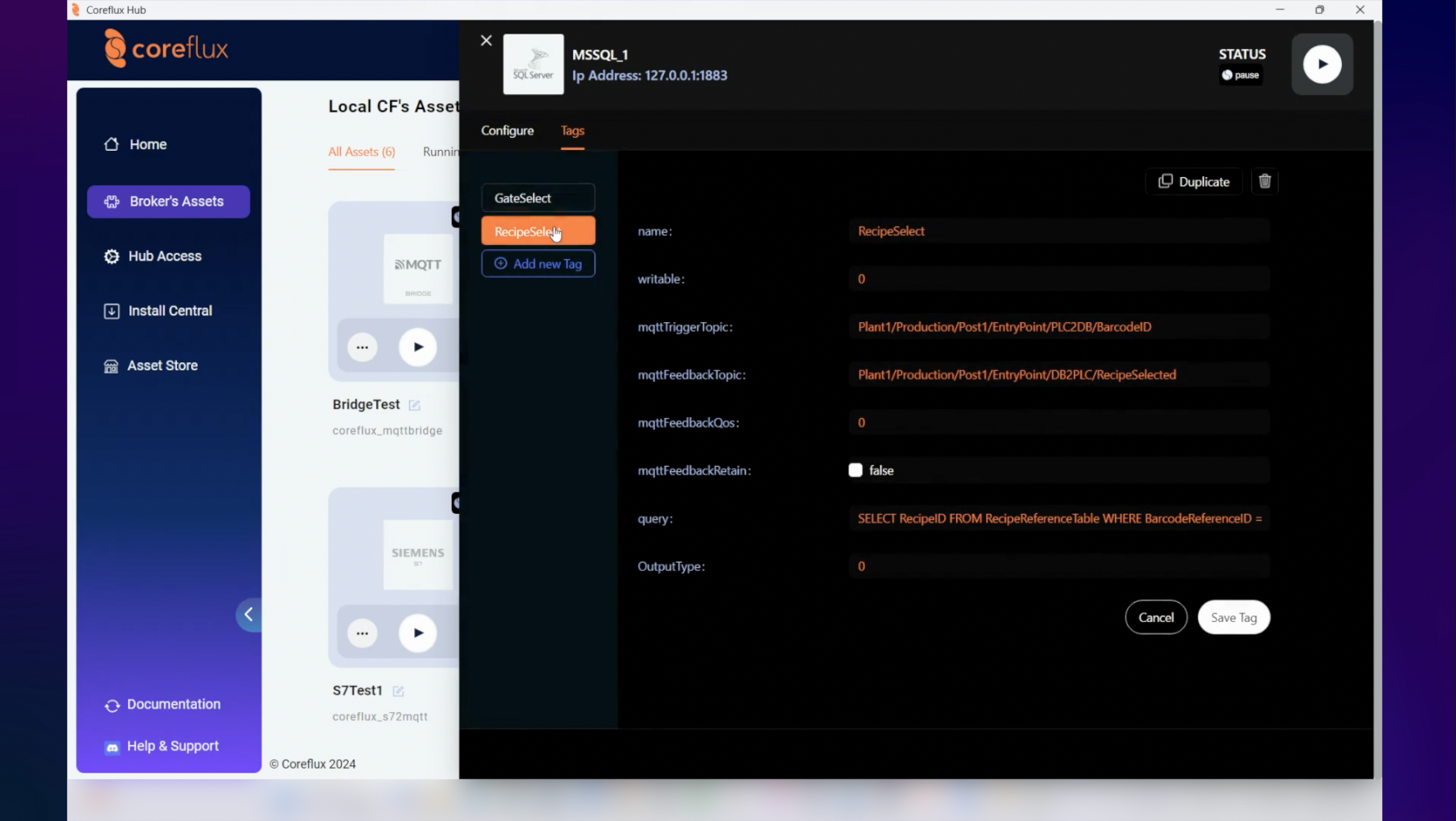

Let's confirm if it's correctly configured on the MSSQL Asset Tags.

Here we have the Recipe Selection and the Topics.

TriggerTopic is BarcodeID, the result is the selection of the value we want, and that result will feed back into the PLC with the corresponding Recipe.

Let's put it to work.

It's showtime

Activating the S7 Asset gives us immediate production data on the Entry Point.

We get the Barcodes, but the parameters are not updating.

In summary

Each time we get a new Barcode:

The database is being consulted,

it fetches the corresponding RecipeID, and

it feeds the PLC back with the appropriate parameters for it.

What you're witnessing is a showcase of a simple architecture that allows you to:

monitor a conveyor system, and

select the routing you wish for different articles.

It's based on centralized information and allows it to be shared with different architectures and PLCs throughout your project.

This is the most straightforward way you could set up an IIoT system and truly have full control at your fingertips.

That's it.

As a thank you for reading till the end…

Here's something for you:

You can get the S7 and the MSSQL assets for free by joining the Coreflux Discord.

Just go to our Vouchers-and-Deals channel and tell us you studied this Use Case really frickin' hard.

Coreflux is on a mission to #democratizeIIoT and empower each human being to extract the maximum potential from the technology they use in their industry.

Visit coreflux.org to power-up your IIoT project.

_________________________________

Use Case: Data collection and validation, applying Unified Name Space ( UNS ), for material tracking

Target Audience: Manufacture industry, IIoT Integrator and Logistics Expert

Technology used: Coreflux Edge Broker, Siemens S72MQTT Coreflux asset ( Siemens to MQTT ), MSSQL2MQTT Coreflux asset ( MSSQL to MQTT ), Microsoft SQL Management Studio

Use Case: Data collection and validation, applying Unified Name Space ( UNS ), for material tracking

Target Audience: Manufacture industry, IIoT Integrator and Logistics Expert

Technology used: Coreflux Edge Broker, Siemens S72MQTT Coreflux asset ( Siemens to MQTT ), MSSQL2MQTT Coreflux asset ( MSSQL to MQTT ), Microsoft SQL Management Studio